The problem

Hand amputations are a significant global issue, with about 7.5 per 100,000 individuals affected annually in the U.S. Of the 3,000 limb amputations each year, partial hand and finger losses are the most common. These injuries occur in various settings, including the military, where hazardous conditions increase the risk. Hand amputations can severely impact functionality and employment, particularly for active-duty personnel.

As global conflicts rise, so do combat-related injuries. Ideally, immediate medical care and rehabilitation with a prosthesis should follow, but high costs limit access. While some prosthetics are covered by insurance, they often lack functionality or require manual adjustments, making them impractical, especially for those with bilateral injuries. More advanced options exist but are often unaffordable.

This gap in accessible, high-functioning prosthetics highlights the need for better solutions to aid recovery for those with partial hand amputations.

Leading to the following problem definition and design goal:

After an ideation phase where multiple solutions and mechanisms were explored, two finger designs were selected

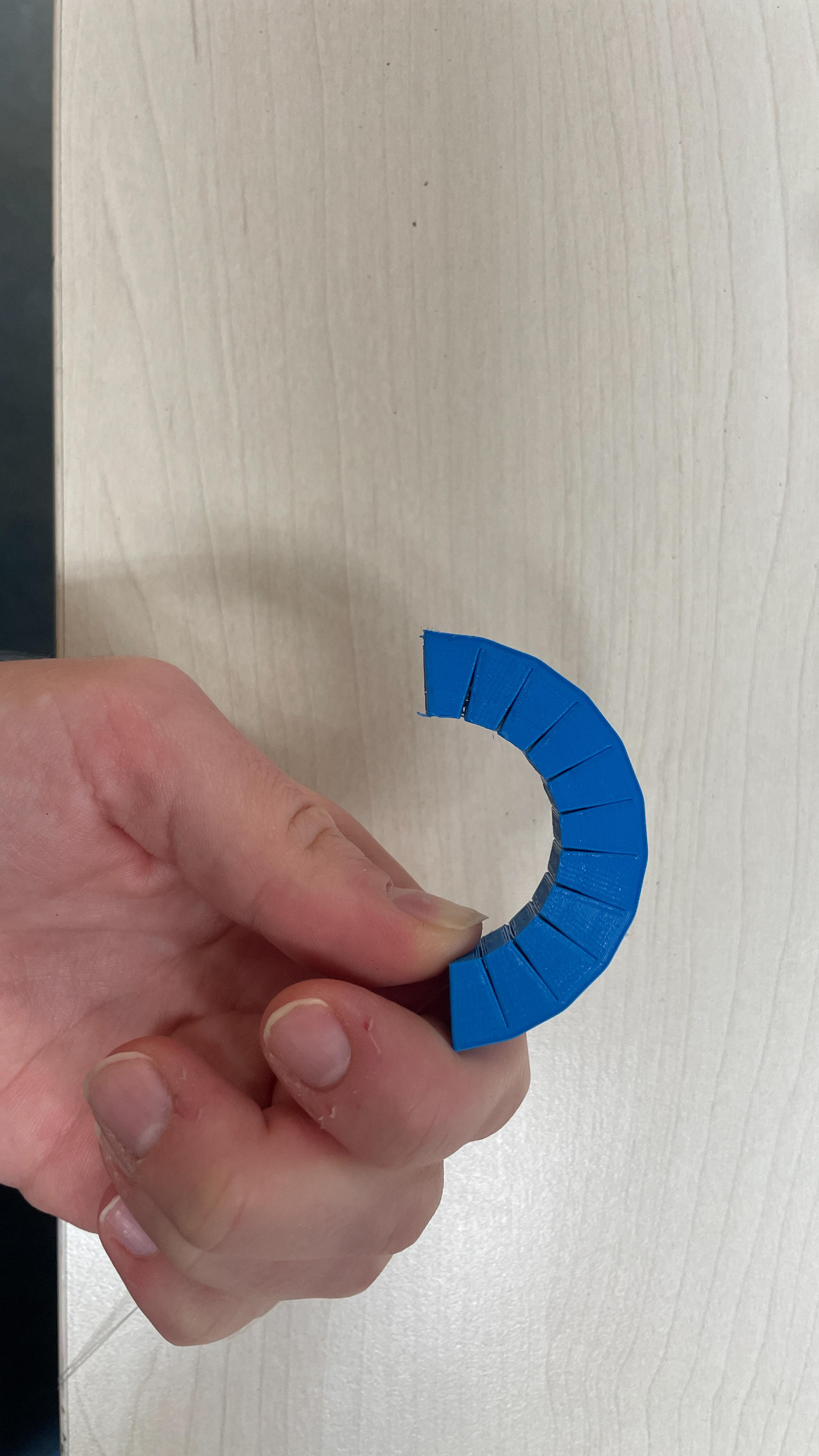

Using compliant mechanisms was found to be the best design direction. A first implementation was done and tested

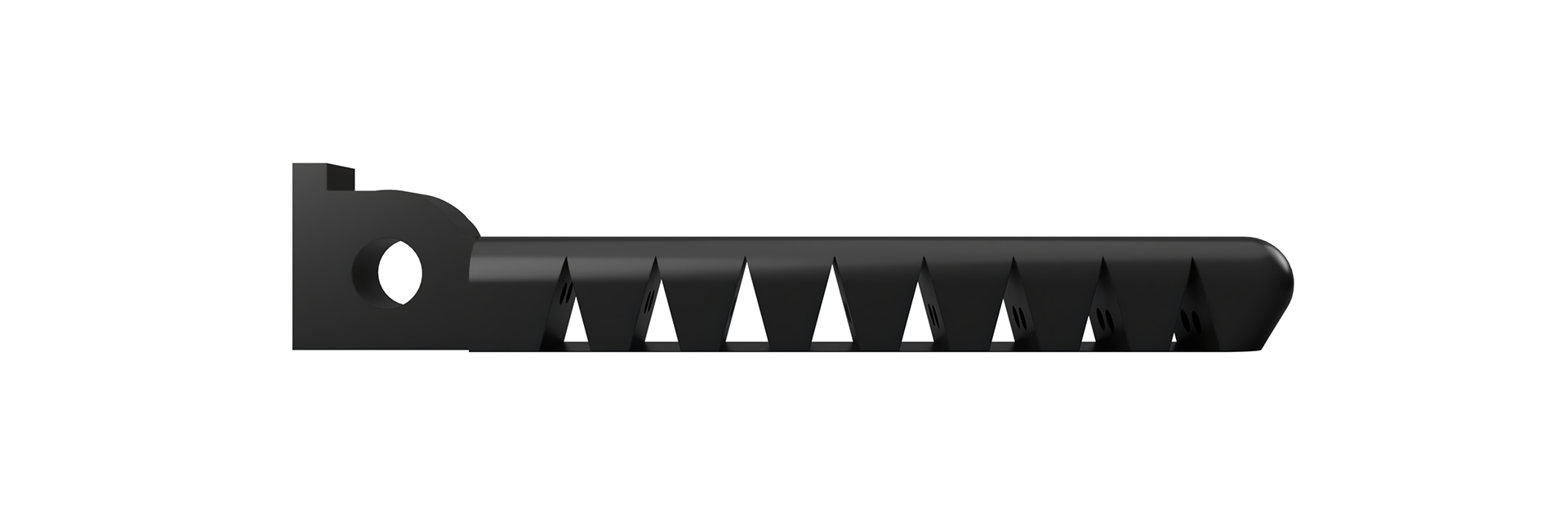

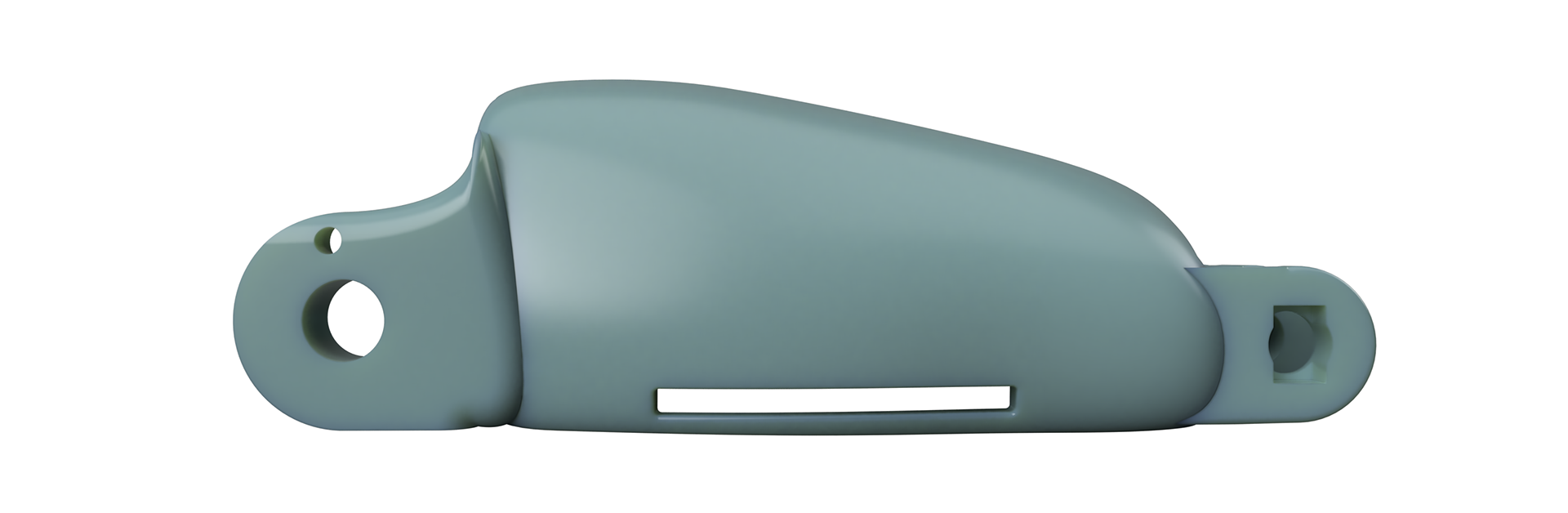

The prosthesis has to be body-powered since this is intuitive for the user and is cost efficient. The prosthesis is activated from the wrist of the user. By flexing the wrist, there will be tension on the wire which will bend the finger. When the force from the wrist is released, the finger will extend.

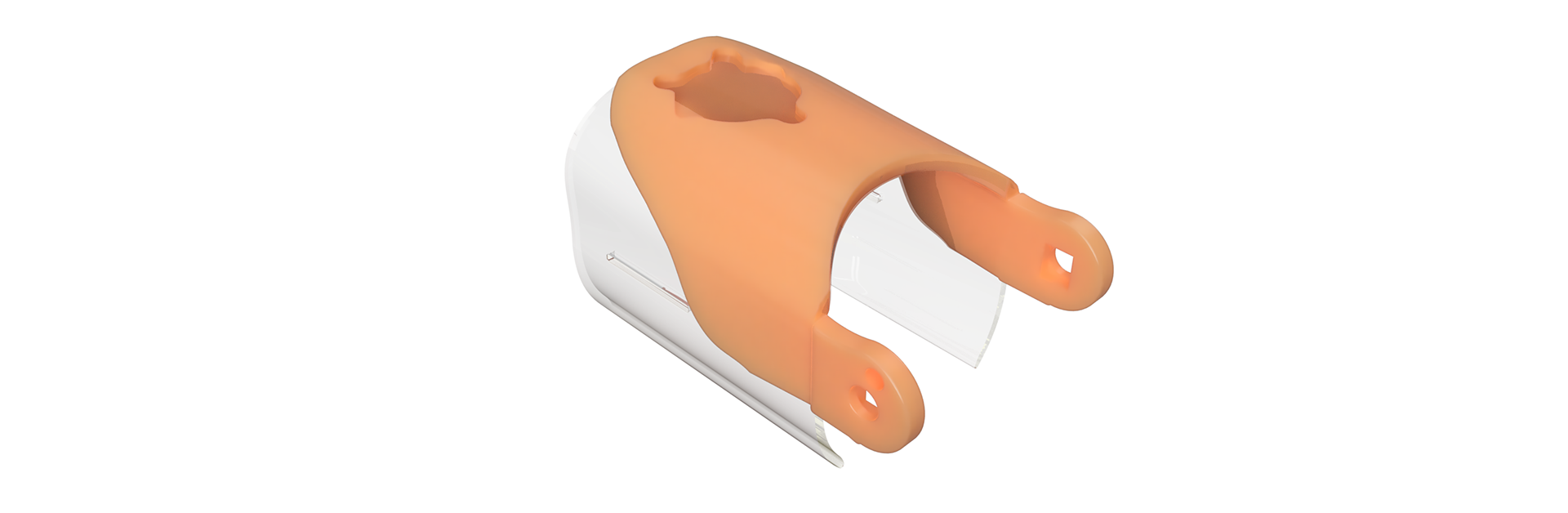

The prosthesis has to be modular, since this will improve the repairability. This makes it possible to repair the prosthesis everywhere and at any time. When a prosthesis breaks, it can simply be repaired instead of waiting until the company created an entire new prosthesis.

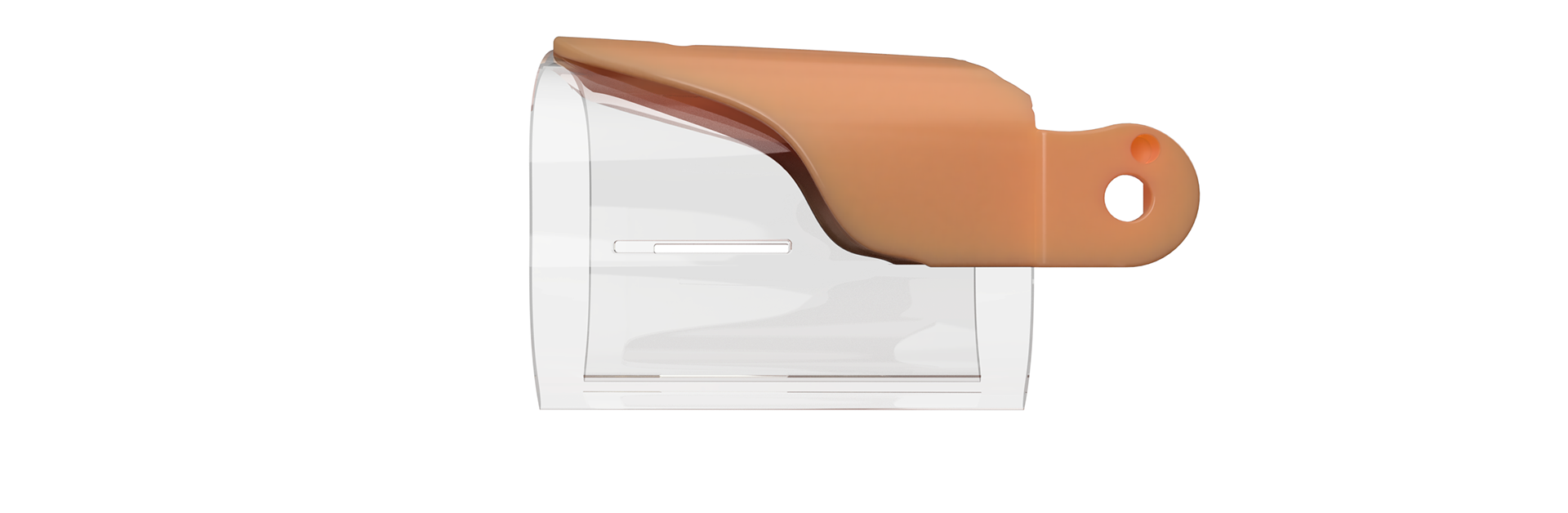

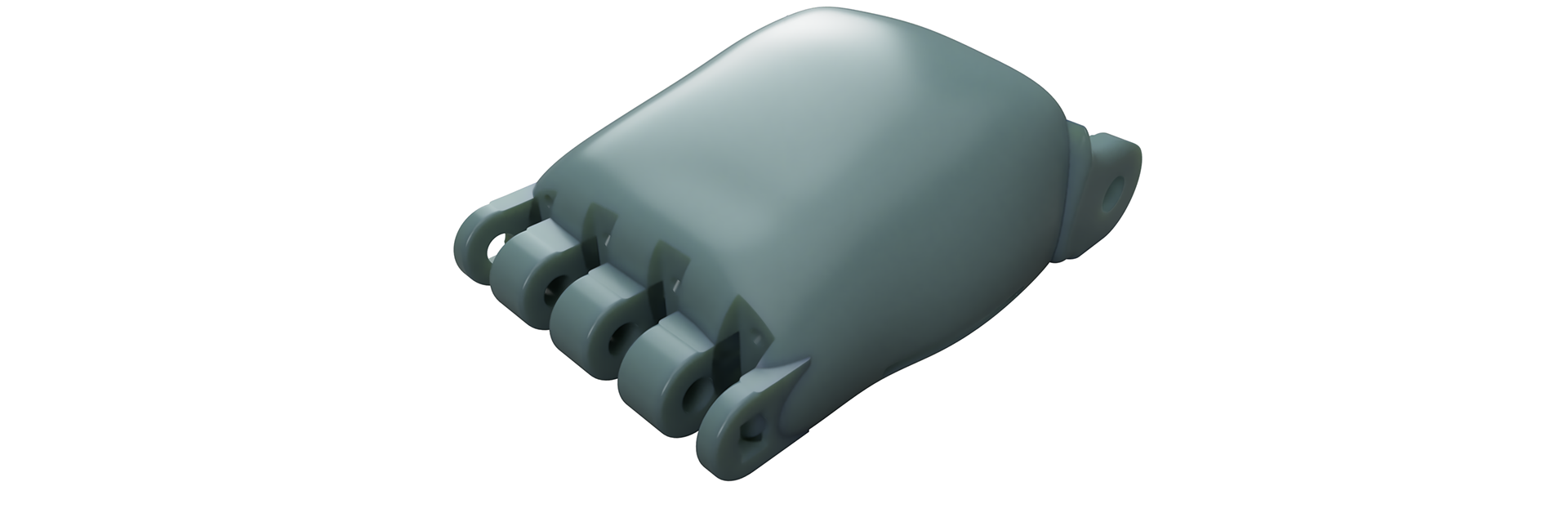

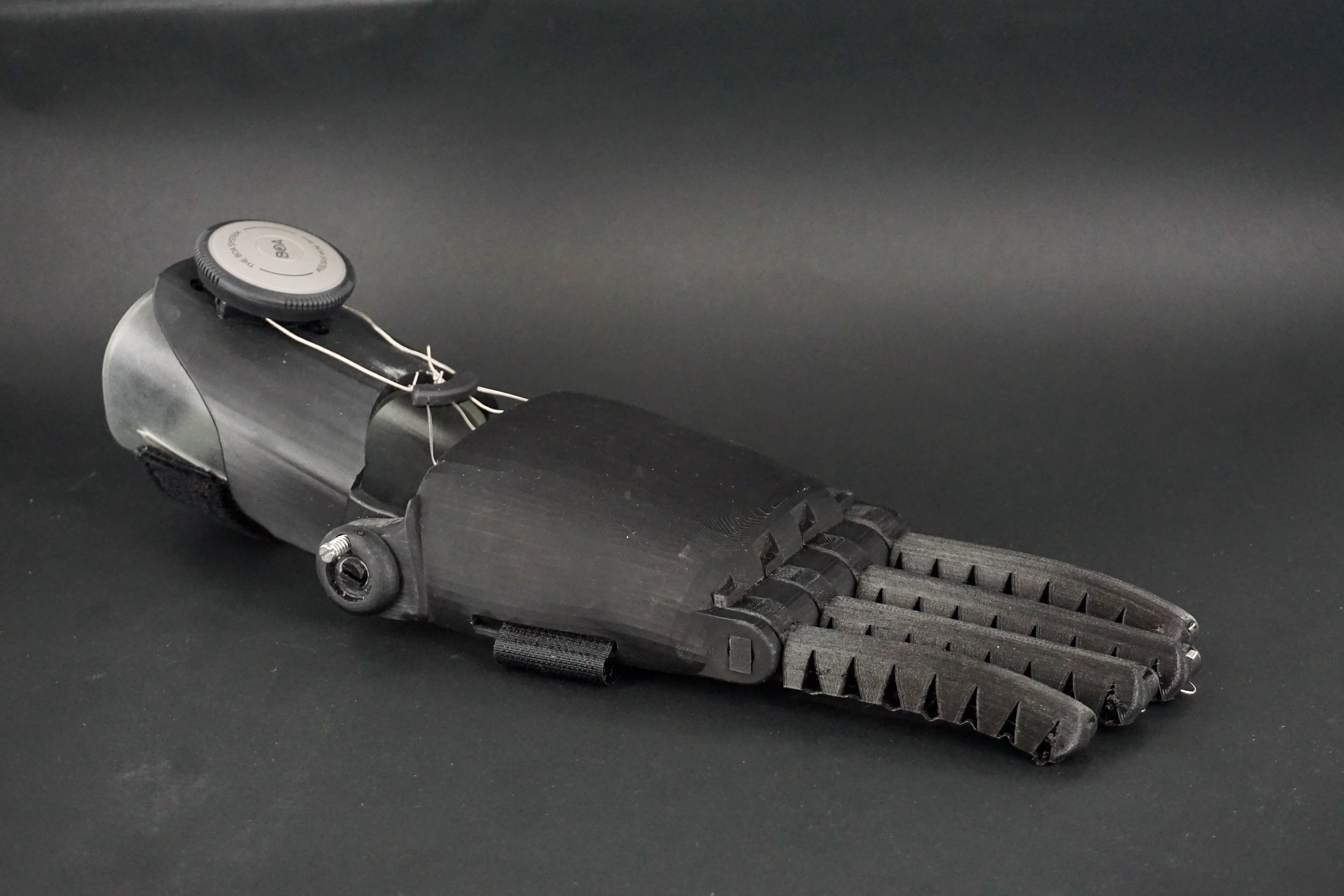

The finger-, hand-, and wrist component were designed separately and connected using different pins. All the parts were 3D printed using a SLA printer.

A clamping system was integrated to make sure that the user does not have to hold their wrist in an inconvenient way. This is a unique implementation that does not exist yet and will improve the usability.

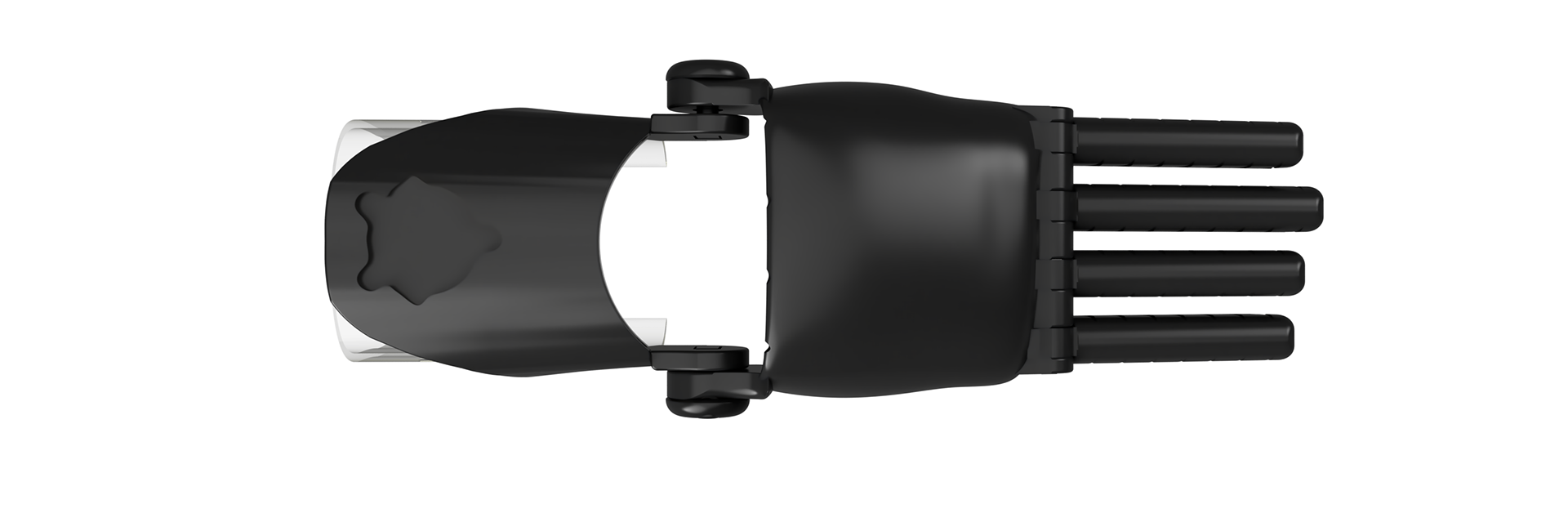

All the components were integrated, resulting in the ExoScorp

Visualization of how the product will be used:

The production technique will be improved in the future, by combining the expertise from the Militair Revalidatie Centrum with this prosthesis design. How the production process will be is visualized

The production costs are estimated to be €154,- and a retail price is estimated to be €802,-. This prosthesis is therefore, affordable for everyone.

This project has resulted in an affordable, modular prosthesis that offers not only cost benefits but also advantages in ease of use, comfort, and aesthetics. The prosthesis is designed to meet the needs of soldiers in rehabilitation, with a focus on customization, production, repairability, and accessibility.

This project has demonstrated that, by using a modular design and an efficient production technique, an affordable body-powered prosthesis can be developed.

The key functionalities targeted for the hand were the tripod grip and power grip. The prosthetic fingers are designed to flex and extend, mimicking the natural motion of a human hand.

This project presents a promising solution to a problem that affects many people and opens the door to future innovations in prosthetic design.

Curious about my project? My report can be seen via this link: